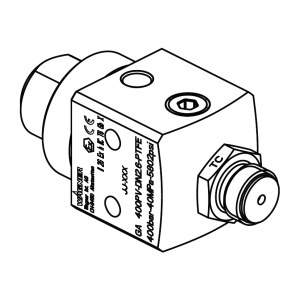

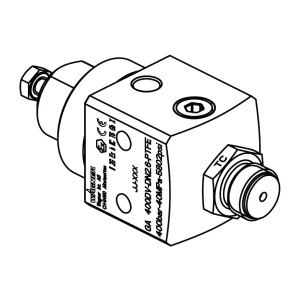

Color change and dosing valves

Material valves

Pneumatically driven color change and dosing valves for the complex and precise processing of paints and multi-component paints. Material valves are characterized by excellent functionality and flushability with high savings potential. The valves are available in various sizes and designs and are made entirely of stainless steel. A range of manual ball valves completes the range.

Benefits

- Flushes very well: Small internal volume and circulation connections for best flushability.

- Made of stainless steel: Made entirely of stainless steel, suitable for all materials.

- For precise color changes: fast-acting pneumatic drive for precise color changes.

- Deliver exact mixing ratios: Finely adjustable injection valve for exact mixing ratios.

- Long shelf life: Mesamoll or solvent template for long shelf life.

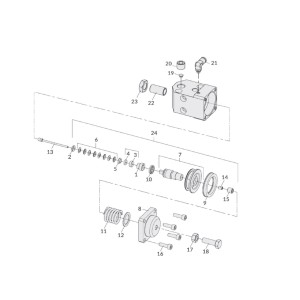

Functional principle

- The control air moves the piston to the left, which opens the valve and releases the flow of material.

- The return spring closes the valve when the control air pressure drops.

- The packing reliably seals the system. The space between the control air cylinder and the packing can also be pressurized with a separating liquid to increase the service life of the packing and piston.

- The free travel of the injection valve and thus the injection quantity can be limited with the adjusting screw (5).

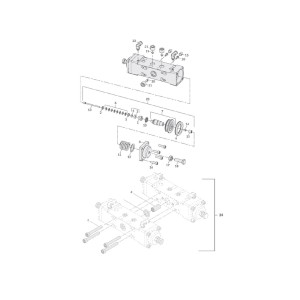

Integration of the valves

- Color change and dispensing valves can be stacked in any way.

- Circulation can be set up at any time for incoming material.

- All valves are combined in a central output line.

- Special connecting elements minimize the dead volume in the valve block.